Technical Engineering Consulting

ECOTECH

ECOTECH provides in-depth expertise in the field of fastening technology and helps you to reduce your costs sustainably. How do we achieve this? With our unique ECOTECH technical consulting service, we identify your optimisation potential in fastening technology and help you to further develop your processes in the best possible and most profitable way.

Our engineering consulting

ECOTECH connection technology – Perfect connections for optimum performance

In a world where precision and efficiency play an increasingly important role, the quality of connections is crucial to the success of projects and products. This is where connection technology comes into play - a key component for optimum performance.

With our ECOTECH consultancy, we are at your side as a leading expert in the field of joining technology to offer you customised solutions. Our in-depth expertise and many years of experience enable us to offer you the best possible support to optimise your connections and make your processes more profitable.

ECOTECH can be used both as a consultancy service for new designs and for optimising existing applications and assembly processes.

Services

Our ECOTECH application areas

Our services are perfectly coordinated: We support you with concrete technical solutions, research and development, measurements directly on the assembly line, and our many years of expertise. Our service is tailored to your needs and perfectly complements our 360° range of services.

Plus factors

Your advantages with ECOTECH at a glance

Whether in mechanical engineering, the rail vehicle industry or the automotive industry – we offer technical consulting solutions for a wide range of industries. We will also find the right screw connection for your individual requirements.

Whether in mechanical engineering, the rail vehicle industry or the automotive industry – we offer technical consulting solutions for a wide range of industries. We will also find the right screw connection for your individual requirements.

We optimise your processes and connecting elements

Through precise analyses using mobile testing devices, we demonstrate possible uses for the optimal screw connection. Whether in our own test field, in your production or at digital or hybrid events.

We can noticeably reduce your production costs

Thanks to our technical expertise and our knowledge of the industry, we determine the right solution for your application with a view to the total cost of ownership. We reduce your assembly costs and significantly increase the effectiveness of your processes.

We conduct our projects using agile and needs-oriented working methods

Our work is technology-neutral and product-neutral. This means we can successfully manage your joining technology projects and support you with prototype development and samples while providing you with the best possible advice.

We shorten your time to market

Our application engineers advise you in the development phase and take essential steps in the development of your fasteners. A shorter product launch process allows you to concentrate fully on the value creation and competitiveness of your product.

We act sustainably

Our mission for our products and consulting services: Promote environmental and economic sustainability – including when selecting materials and manufacturing processes. We aim to create a lasting connection!

»"There is still a basic tendency to underestimate the opportunities for cost savings through optimised joining technology!"

Our technical consulting is at the heart of our services in joining technology

We analyse your product, your production processes, and the joining technology used in them down to the smallest detail. We use this comprehensive assessment to identify areas of potential optimisation where you can rationalise the fasteners in your value chain. We offer comprehensive advice on optimising your screw connections, which can significantly reduce your procurement costs for fasteners and simplify your purchasing and assembly processes. Perfecting your joining technology with ECOTECH enables you to optimise and significantly reduce your process and production costs. With our help, you can achieve a competitive advantage as early as the product development phase.

With our unique technical consulting, we analyse your specific requirements and challenges. We work with you to develop a bespoke solution that meets your needs and is tailored to your individual processes. We strive to fully exploit your optimisation potential in joining technology and help you achieve the best possible performance.

At ECOTECH, quality and customer satisfaction are top priorities. We therefore rely on the highest standards in joining technology. Our products and solutions are subject to strict quality controls to guarantee you outstanding performance and a long service life.

Our ECOTECH technical service is our core service. Using the latest analytical methods and innovative technologies, we uncover possible weak points and potential for improvement in your connections. We use advanced materials and manufacturing techniques to provide you with the most reliable and efficient connection solutions. Our goal is to optimise your processes, reduce costs and promote the sustainability of your products.

ECOTECH – your expert for optimising assembly and procurement processes

Our ECOTECH experts carefully analyse your current processes and identify potential options for improvement. Using innovative technologies alongside tried-and-tested methods, we develop custom solutions tailored to your specific requirements. Our goal is to make your assembly and procurement processes more efficient and cost-effective, enabling you to gain a competitive advantage.

Using modern digital solutions and automation techniques, we support you in implementing more effective workflows and optimising your supply chains. This allows you to reduce costs while also improving the quality and efficiency of your processes.

In collaboration with you, we develop individual solutions that sustainably simplify your procurement processes for fasteners, enabling significant savings. You can count on our eBusiness specialists as well as our experienced sales team.

You can trust ECOTECH to take your assembly processes to the next level. Together, we achieve perfect connections that meet your requirements and give you a competitive advantage. Contact us today to find out more about our comprehensive services and custom solutions. We look forward to supporting you with your connection projects.

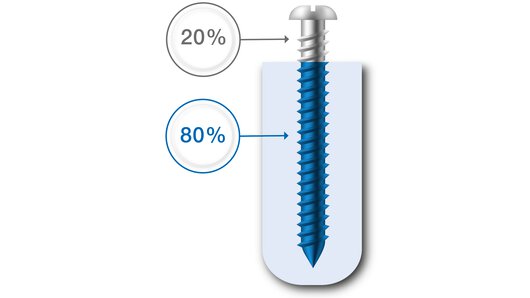

The 80/20 principle of manufacturing costs

Reduce manufacturing costs with ECOTECH consulting

Screw connections – reliable stability and precision for your project

Screw connections are indispensable in many areas of industry and construction. They provide an effective method for connecting various components safely and securely. But screw connections are not just simple mechanical connections – they also play a crucial role in terms of reliability, resilience and longevity.

When developing and implementing a project, it is vital to select the right screw connection. Factors such as material, thread type, tightening torque and torque control come into play here. To ensure that your screw connections meet the requirements and maintain their long-term performance, it is essential to seek expert advice and expertise.

ECOTECH is your experienced partner in the field of screw connections and offers you comprehensive solutions for your specific requirements. Our team of experts has in-depth knowledge of joining technology and will support you in selecting the best screws, threads and fasteners for your project.

Using the most modern technologies and methods, we analyse your requirements and take into account factors such as resilience, vibration-resistant connections, corrosion protection and ease of maintenance. Our experts will help you choose the right screw connections to ensure reliable stability and precision.

We also offer you support in assembling and commissioning your screw connections. We ensure that correct tightening torques are maintained and connections are installed correctly for optimal results. Our experience and technical expertise enable us to optimise your screw connections to the highest level.

With ECOTECH as your partner, you can be sure that your screw connections meet the highest standards. We attach great importance to quality, reliability and efficiency. Our products and solutions undergo strict quality controls to guarantee you long-term performance and durability.

You can trust ECOTECH to find the perfect screw connections for your project. Contact us today to learn more about our comprehensive solutions and screw connection expertise. We are ready to support you with your challenges and help you achieve the best possible stability and precision.

Technical solutions

ECOTECH develops technical solutions that optimise your joining technology with product-independent engineering. Our application engineers will recommend the best screw connections regardless of the manufacturer. With innovative tools, CAE-based designs and rapid prototyping, we develop individual fasteners and applications for you.

Research and development

Material testers in our accredited testing laboratory carry out mechanical and physical tests using the finite element method (FEM). Our expertise is always up to date through collaborations with research institutions and universities. The results of our research and development are reflected in our own innovations and patents.

Series production optimisation

To optimise your production and assembly processes, we systematically analyse your production line. We perform vibration tests or determine friction coefficients for precise practical data.

We also perform value analyses and tear-down analyses in our laboratory. We achieve cost savings through standardisation and optimisation of the manufacturing processes.

ECOTECH believes in knowledge transfer

You benefit from our expertise in joining technology, project forecasting and risk management, our membership of core industry associations and customer seminars.

We provide a range of technical content in various publications, and our “Tech Days” support you in technical topics. All of this ensures that you benefit from our advice over the long term.

Frequently asked questions

FAQs about technical advice from ECOTECH

The focus is on optimising joining technology and finding solutions to related challenges. This results in rationalisation of the fasteners and improvement in C-parts management. This means that new and existing screw connections are adapted and the variety of parts is reduced, thereby reducing the total cost of ownership.

Standardisation and reduction increase sustainability in terms of using the right material and the right surface. We will analyse your product and the joining technology it uses down to the last detail.

At ECOTECH, our mission is to demonstrate optimisation potential. Our application areas are perfectly coordinated: Our service includes technical consulting, research and development, optimisation of your production line and knowledge transfer. Each of these areas is personally adapted to your needs – we call this all-round service our 360° joining technology.

At work for you - our ECOTECH experts As part of our ECOTECH process optimisation, we use a variety of state-of-the-art methods to optimise your processes. We have measuring devices and mobile testing devices for series production optimisation. In addition to CAE-based designs, rapid prototyping and tear-down analyses we also use the finite element method (FEM) and joining technology value analyses as well as project forecasting to achieve an optimal result. We also use high-quality products, such as suitable thread locking, to optimise the fastening technology and to create a safe product.

Optimise your processes with ECOTECH – arrange a free consultation now!

Bandbegehungen in der Produktion The manufacturing costs for a new product are already largely determined during the design phase. The cost-effectiveness of joining technology depends only to a minor extent on the pricing of the fasteners. The process costs for the preparation and assembly of the components to be joined are much more significant. Calculation, interpretation, design and construction are not just technical terms for the ECOTECH team, but a true passion.

Our all-round service consists of providing technical solutions, series production optimisation, outstanding expertise and research and development. We rationalise and standardise your C-parts, thereby reducing the variety of parts. We recommend a cost-effective selection of fasteners.

All measures are aimed at achieving optimum efficiency and productivity, as well as achieving cost savings and a reduction in manufacturing costs early in the process. The earlier ECOTECH specialists are involved, the greater their positive impact on the entire value chain and on manufacturing costs.

What measures are being taken to reduce production costs? Optimisation begins with our technical consulting. ECOTECH optimises your joining technology through specially developed technical solutions and through the rationalisation of your fasteners. We use product-independent, technology-neutral engineering.

Innovative products, such as screw locking with the RIPP LOCK® prevent production downtimes, technical damage, loss of time and high costs, and increase safety through effective and economical unscrew locking. We also advise you on surface selection and thread locking.

With our experience in application technology we can recommend the most economically practical joining technology and work with you to develop your screw connections. This is how connections are created to construct perfect products. The high technical standards of our research and development test area ensure the best possible quality.

Furthermore, our <strong>customer seminars and training courses</strong> provide additional know-how, which enables long-term quality assurance of the production processes.

Optimisation through innovative products

Download

The ECOTECH brochure

All information in one place!

are happy to help you

Do you have any questions or a current project?

Let us know – we will get in touch with you

Contact us